Microwave Inspection and Testing

Microwave Inspection and Testing of Composites

Manufacturing defects, matrix deterioration, and other flaws are difficult to detect using traditional methods and destructive testing of composite materials can be costly, time consuming, and it may not yield the appropriate insights for manufacturers. This is why nondestructive testing methods such as microwave testing are rapidly growing - usefulness, low cost and convenience.

Manufacturing defects, matrix deterioration, and other flaws are difficult to detect using traditional methods and destructive testing of composite materials can be costly, time consuming, and it may not yield the appropriate insights for manufacturers. This is why nondestructive testing methods such as microwave testing are rapidly growing - usefulness, low cost and convenience.

What is Microwave testing?

Microwave testing is a nondestructive testing method (NDT) that is used to find embedded defects within materials or structures. This method is most commonly used to test dielectric materials such as plastics, glass-fiber reinforced plastics (GFRP), ceramics, plastic foams, wood, wood-plastic composites (WPC), and other composites.

How does it work?

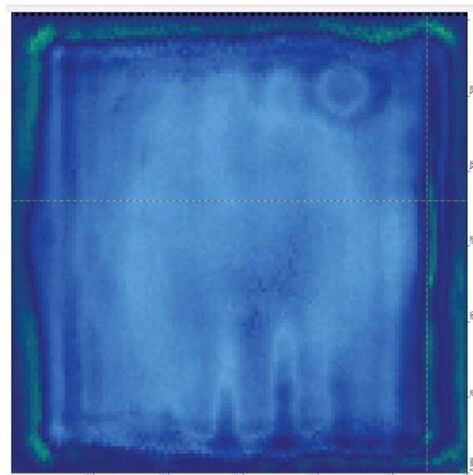

Microwave testing uses electromagnetic radiation in the microwave frequency range for inspection services. Specialized inspection equipment and methods couples multi-frequency data collection using Vector Network Analyzers with specifically designed antennae. The use of a bespoke antenna system for specific materials and conditions tremendously improves the response of the device and allows for enhanced defect detection and sizing.

The Benefits of Microwave testing:

- The tested specimen is not damaged

- Highly effective in finding defects

- Great for spotting early deterioration signs

- The item can still be used after testing if not defective

- Relatively quick procedure and cost effective compared to other methods

What we provide:

BHC Associates works with the most cutting-edge advanced microwave imaging system. The bespoke antenna system is the most advanced system used for microwave imaging. The antennae provide enhanced defect detection and sizing. The antennas also come with broadband features which allow for more frequency ranges to be used during inspection. Our multi frequency system has the ability to clearly illustrate all embedded flaws and the depth of the flaws can also be ascertained with great accuracy. Don't settle for less. Contact BHC Associates to learn more about our advanced microwave inspection services.