February 2023 Composites Blog

February 17, 2023

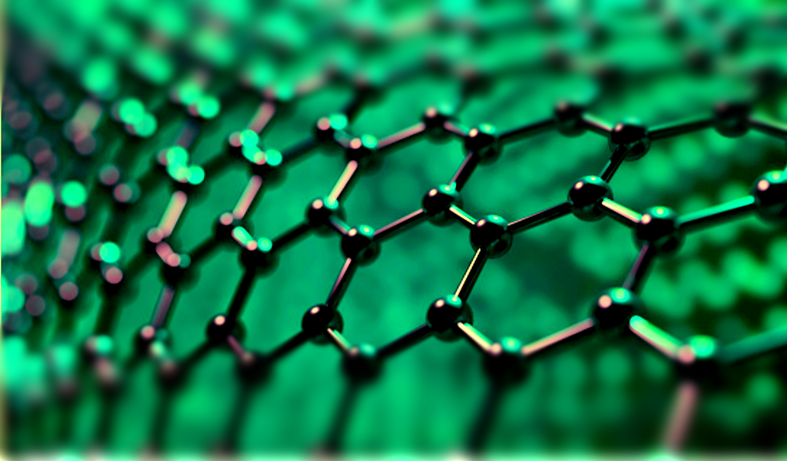

Researchers Create New and Improved Low-Cost Carbon Fibers

A group of Korean researchers collaborate to develop cost-effective production technology for carbon-nanotube-based composite carbon fibers with extremely high tensile strength and high modulus. This new material is expected to be used in several industries including military, aerospace, and various others. Carbon nanotubes are more than 100 times stronger than steel while only being one-forth of the weight, and they are also electrically conductive, having similar conductivity to that of copper. Nevertheless, maintaining the superior properties of carbon nanotubes in fibers is very difficult and the extremely high costs of carbon nanotubes make commercialization unfeasible. Researchers were successful in developing a technology that improved the modulus of the fibers while maintaining the overall strength. They did this by combining carbon nanotubes with polyimide composite fibers utilizing a continuous wet spinning process and then applying a high-temperature heat treatment. They were able to replace up to 50% of the carbon nanotubes with lower cost polyimide. Learn more here.

February 28, 2023

Efficient composite curing process must meet high demand in the urban vehicle industry

Efficient composite curing process must meet high demand in the urban vehicle industry

Project EUVAM at the University of Stuttgart in Germany is developing a new UV composite curing process to be used in the manufacturing of lightweight composite components for small urban vehicles . The demand in the mobility and micro vehicle industry lead researchers at Stuttgart to start developing more efficient manufacturing processes that can meet this demand in an efficient and cost effective way. The micro vehicle industry is very stringent when it comes to new processes as many different aspects are key to dictating the adaptation of a given process. That is to say that in addition to efficiency the process must be able to produce quality light weight materials and do so in a digitally controlled, economical , and sustainable way . The scientist believe that this new UV curing technique will make isothermal process control for polymer curing in resin transfer molding (RTM) or in the wet pressing process obsolete, thereby reducing time to completion and cutting costs. Learn more here.