April 2024 Composites Blog

Scroll Down for more content!

Scroll Down for more content!

April 8, 2024

New Compound has the Potential to Advance Communication Technology

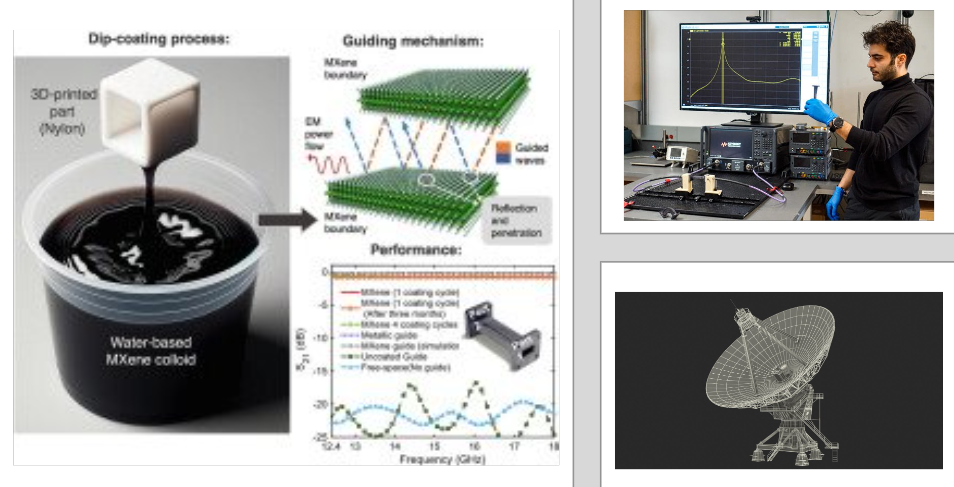

Researchers from UBC Okanagan collaborated with Drexel University to synthesize a new compound that can replace metals and improve performance in antennas and other communication devices. The researchers created the compound by combining a polymer with a MXene compound, and they attest that it is capable of replacing metallic counterparts and significantly improving current communication technologies such as antennas, waveguides, and filters. What's more, the new compound can be used to 3D print these essential communication components with high precision. Waveguides are essential in many technologies; they function by helping direct sound and optical waves in communication devices and other technologies. Now thanks to emerging MXene compounds the waveguide manufacturing process is much easier, more cost effective, and the product is much lighter and performs comparably when compared to conventional waveguides that use metals. MXenes are a family of two-dimensional materials that are gradually emerging in the technology sector. An example of MXenes’ success is titanium carbide MXene which has become a leader in electrical conductivity. Dr. Yury Gogotsi suggests to "Think of MXenes as nanometer-thin conductive flakes that can be dispersed in water-like clay," he further mentions that "This is a material that can be applied from dispersion in pure water with no additives to almost any surface. After drying in air, it can make polymer surfaces conductive. It's like metallization at room temperature, without melting or evaporating a metal, without vacuum or temperature.” Learn more about this topic here.

April 22, 2024

Boeing Whistle Blower Criticizes Composite Structure on 787 Dreamliner

Boeing Whistle Blower Criticizes Composite Structure on 787 Dreamliner

Boeing whistle blower expressed concerns over the company’s 787 Dreamliner plane’s composite structure. The 787 Dreamliner is a wide-body plane that makes extensive use of composite materials. Generally, composites are considered high performance materials, boasting extreme strength and lightweight properties. However, the materials are only as good as an aircraft’s design build and in this case Boeing quality engineer Sam Salehpour noted that there was a serious issue with the Dreamliner’s structure. Specifically, Mr. Salehpour mentioned that sections of the plane’s fuselage were not properly fastened together and that this could cause structural failure over time. The federal Aviation Administration is investigating his claims. Salehpour also testified before a senate panel where he further detailed the situation and how the company reacted to his concerns. To counter Salehpour’s claims Boeing held a briefing for reporters at its North Charleston, S.C., where two of the company's top engineers were present to address questions and present their own analysis of the issue. Vice president and the functional chief engineer for mechanical and structural engineering, Steve Chisholm mentioned the following; “Not only did we interrogate those airframes — we were taking out fasteners, we were looking for damage, we’re also doing the approval inspections to understand the build condition, and we didn’t find any fatigue issues in the composite structure.” investigations are still ongoing. Learn more here.