December 2023 Composites Blog

December 8, 2023

Startup Company Cambium Looks to Reinvigorate the Advanced Materials Sector

Startup company Cambium looks to reinvigorate the advanced materials sector by using an innovative computer platform to mine biology for molecules and facilities that can be used to make advanced composite materials. The company recently received $19M in a Series A funding round to continue the development of advanced biomaterials for next generation hardware applications. The company was founded in 2020 with the goal of reinventing advanced material development for the aerospace, defense, automotive, and other industries. Using their discovery platform that acts as a “molecule to machine” innovator the company is able to mine the world of complex biological systems for molecules and facilities that produce the composite, which can then be tested in the real world. Cambium founder Simon Waddington noted “We need to be able to go right back to the molecule, look at what the problem is, redesign molecules from the ground up – but with manufacturing in mind, Then we need to actually make those molecules, we need to test them, we need to go into proof of concept and go all the way down.” After collaborating with the Naval Air Warfare Center Weapons Division on a project to make biobased high temperature composites for UAVs and a myriad of other military vehicles, the company expanded into three main business segments including high temperature lightweight polymers, higher temperature materials for hypersonic applications, and lastly emerging domains, such as laser protection for satellites. Cambium will surely use their recently acquired funding to continue to innovate in the advanced materials and composites sectors. The funding round was led by 8VC, also participating were Veteran Ventures, MVP Ventures, Marlinspike, GSBackers, Gaingles, Kurn Venture Fund, Jackson Moses, Vertical Capital, and angel investors. Learn more here.

December 16, 2023

New Material as Tough as Diamonds Has Potential for Industrial Applications

New Material as Tough as Diamonds Has Potential for Industrial Applications

After decades of failed attempts scientists were finally able to synthesize carbon nitrides, which rival diamonds as the hardest material on earth. Experts say this breakthrough could enable the use of multifunctional materials for industrial purposes such as high endurance cutting instruments, coatings for cars and spaceships, solar panels and photodetectors. Scientists synthesized carbon nitrides by subjecting carbon and nitrogen molecules to extreme pressure and heat. Additionally, they found that carbon nitrides were tougher than cubic boron nitride, one of the hardest materials on earth, second only to diamonds. The breakthrough was made by an international team of researchers from the University of Linkoping (Sweden), University of Edinburgh and University of Bayreuth (Germany). Three carbon nitride compounds were found to have the properties for extreme hardness, and they were able to retain their diamond like toughness after returning to normal pressure and temperature conditions. More experimentation revealed that the materials could also contain other properties including high energy density and photoluminescence. Learn more about this topic here.

December 31, 2023

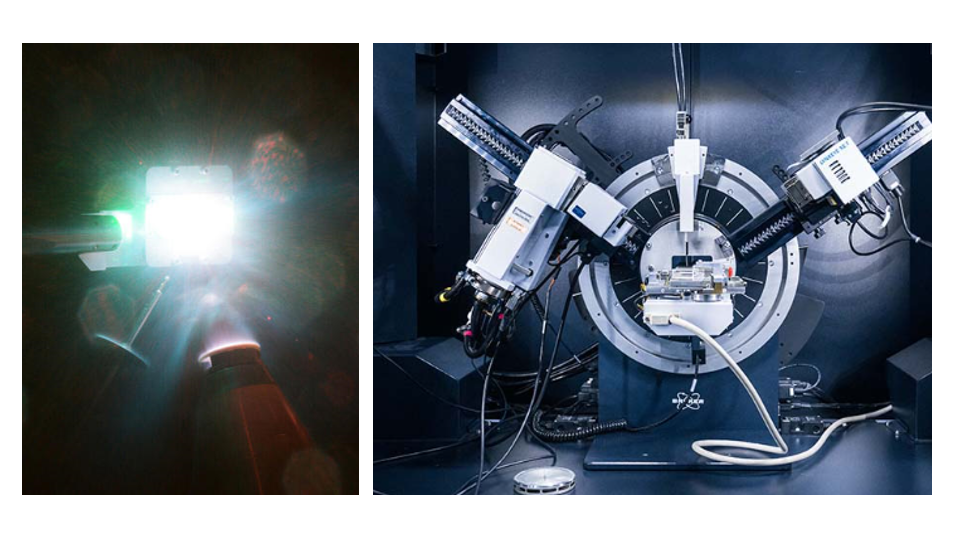

Deep learning Boosts Gold Standard Materials Characterization Technique

Deep learning Boosts Gold Standard Materials Characterization Technique

X- ray diffraction experiments are employed to analyze a material’s structure and properties. Now scientists have found a way to supercharge this technique with deep learning, enabling exciting possibilities in the world of materials science. The interdisciplinary team of researchers from the University of Rochester developed machine learning models that can sift through massive amounts of data produced by X-ray diffraction experiments and thereby help uncover valuable insights about a material’s characteristics. Niaz Abdolrahim, project lead and professor in the Department of Mechanical Engineering and a scientist at the Laboratory for Laser Energetics (LLE), mentioned that there is a lot of data, physics, and materials science hidden in the images produced from X-ray diffraction. Further, he noted that “developing a good model to analyze this data can really help expedite materials innovation, understand materials at extreme conditions, and develop materials for different technological applications." To train their deep learning models, the researchers used real- world data from past experiments with inorganic materials. Learn more about this topic here.