August 2022 Composites Blog

August 14, 2022

Siemens Gamesa Debuts RecyclableBlades at RWE Offshore Wind Farm

Spanish-based Siemens Gamesa has installed their composite RecyclableBlades at the Kaskasi offshore wind farm ran by German company, RWE. This moment marks a milestone in the long-term sustainability of offshore wind power. The RecycleableBlade technology was released in September 2021, and this installation marks its first major, commercial use. Marc Becker, CEO of the Siemens Gamesa Offshore Business Unit notes how impressive this turnaround is and how it sets the pace that efforts to combat the global climate emergency should be taken at. RecyclableBlade technology enables 100% reclamation at the end of the product’s life span. The resin, fiberglass, and wood that comprise the blades are easily separated using a mild acid solution and will be fully usable in other product applications. More turbines at the Kaskasi wind farm (located in the German North Sea) are earmarked to be equipped with Siemens Gamesa RecyclableBlades in the near future. Learn more here.

August 30, 2022

Toray Carbon Magic Joins HAKUTO-R Lunar Exploration Program

Toray Carbon Magic Joins HAKUTO-R Lunar Exploration Program

Ispace, Inc. has been at the forefront of recent space exploration efforts, launching their HAKUTO- commercial lunar exploration program. Recently, Toray Carbon Magic Co. Ltd. Announced that it will be joining the project. Toray brings years of composite materials expertise in addition to design and aerodynamics know-how to the project and is already fabricating components of lunar rovers and landers. Toray Carbon Magic president, Akiyoshi Oku says that the company shares ispace’s vision of extending the human presence to space and believes that their lightweight carbon fiber-reinforced materials will greatly aid the project. The HAKUTO-R project as of now has two launches scheduled, the first being a soft lunar landing this year. The second launch is scheduled for 2024 and will involve both a lunar landing and rover deployment. Read more here.

August 30, 2022

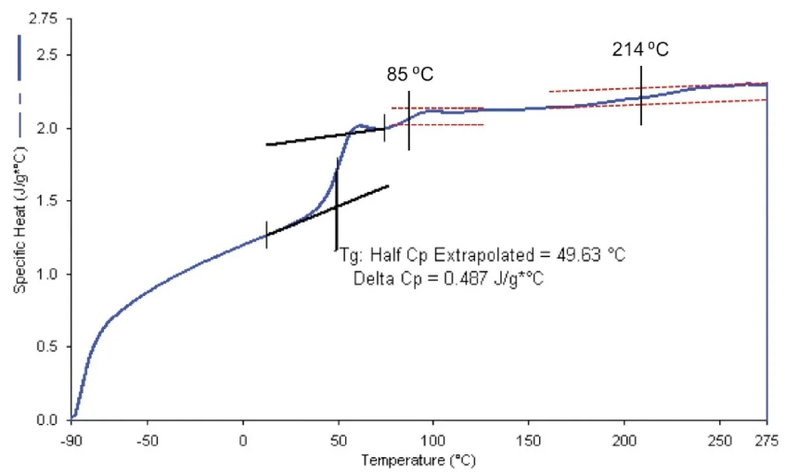

Specific Heat Capacity Determination of Nanocomposites to Improve the Properties of Thermoplastics

In this study Christophe Schick suggests that the strength or weakness of the chemical link between the nanomaterial filler and the RAF can be an indicator of the functionality of the nanocomposite as well as how quickly it degrades in the environment. HyperDSC is a method verified by Christophe Schick to access RAF and to look for signs of RAF devitrification between room temperature, the glass transition temperature, and the rate suppressed start of decomposition. He suggests that hyperDSC has the potential to clarify nanocomposites. He believes that the top temperature range for which precise heat capacity test are feasible is increased using the quick heat-cool approach illustrated in this article. Consequently, it is believed that this approach may make it easier to spot the devitrification or the lack of nanocomposite bonding, that occurs in amorphous polymer systems. Read more here.