3D Stress Analysis Consultants

3D Stress Analysis Consulting:

Our Composites group provides a wide range of stress consulting services and solutions to meet your needs and to help validate your part designs before the production process.

Our Composites group provides a wide range of stress consulting services and solutions to meet your needs and to help validate your part designs before the production process.

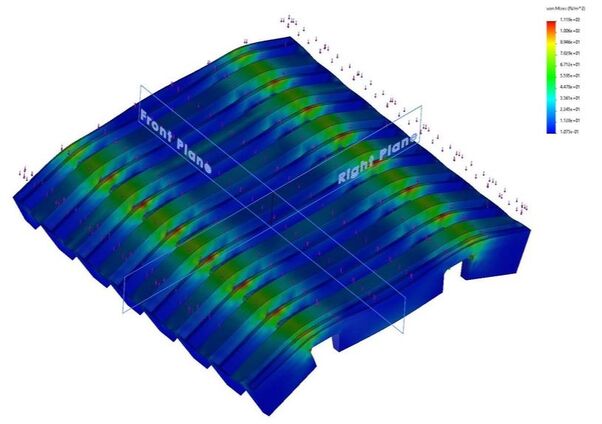

Engineers design parts and products with specific factors in mind. Guaranteeing that they will proceed as expected by their service environment, this is the difference between an effective design and a near structural failure. One of the essential techniques used to gauge how well a design will endure the stresses endemic to its service conditions is called finite element analysis, also known as FEA.

Finite Element Analysis is, by definition the use of calculations, models, and simulations that anticipate and know how an object could behave under different kinds of physical conditions. Using FEA can determine possible design issues so that changes can be made in the early stages of development making it a cost effective way of ensuring the structural integrity of the part or assembly being analyzed.

Finite element analysis can not only just indicate the regions under the most stress when placed under a load, but it can additionally simulate other phenomena. Vibration, liquid flow, heat transfer, and other stimuli can undermine structural integrity over a period of time can all be simulated.

Quality is Our Top Priority:

Our Composites Teams dedicates themselves to supplying services of outstanding quality, to guarantee we deliver the finest customer experience. If you are looking for finite element stress analysis from a stress analysis consultant, click the button below and contact BHC Associates today!

Finite Element Analysis is, by definition the use of calculations, models, and simulations that anticipate and know how an object could behave under different kinds of physical conditions. Using FEA can determine possible design issues so that changes can be made in the early stages of development making it a cost effective way of ensuring the structural integrity of the part or assembly being analyzed.

Finite element analysis can not only just indicate the regions under the most stress when placed under a load, but it can additionally simulate other phenomena. Vibration, liquid flow, heat transfer, and other stimuli can undermine structural integrity over a period of time can all be simulated.

Quality is Our Top Priority:

Our Composites Teams dedicates themselves to supplying services of outstanding quality, to guarantee we deliver the finest customer experience. If you are looking for finite element stress analysis from a stress analysis consultant, click the button below and contact BHC Associates today!